|

|

| ProSelect™ Tannin (P/N ER20001) is the choice for color, organics, and tannin contaminated waters. It works as an organic screen, either as a stand-alone prefilter for a softener, or in some applications as a media which is simply added to an existing softener. ProSelect Tannin will sit on top of the existing softening bed to protect it and remove organic (heme) iron as well. ProSelect Tannin is iron resistant, regenerates with salt, and is the resin of choice for heme iron applications. |

| |

| |

| APPLICATIONS: |

| • |

Remove Naturally Occurring Organics |

| • |

Remove Tannin |

| • |

Remove Organic Color |

|

| |

| |

|

| |

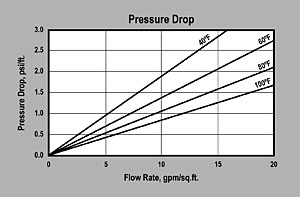

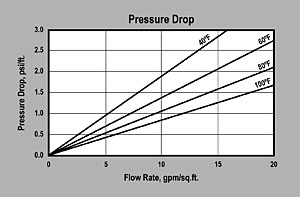

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

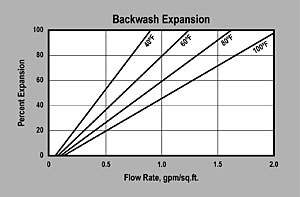

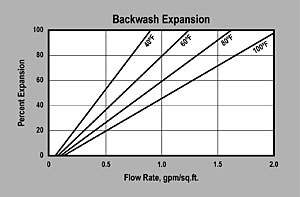

| BACKWASH — After each cycle the resin bed should be backwashed at a rate that expands the bed 25 to 50 percent. The graph above shows the expansion characteristics as a function of flow rate at various temperatures. |

| |

| |

|

| |

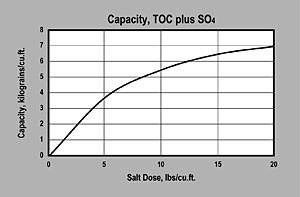

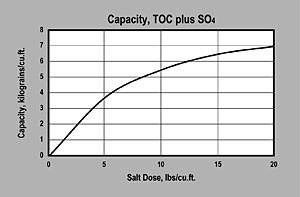

| CAPACITY — The graph above is based on 2 gpm/cu.ft. flow rate, pH near neutral, and 36 inch minimum bed depth. Capacity is for TOC plus sulfate. No engineering downgrade has been applied. |

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide

Iron Removal Comparison Chart

|

| |

| |

| ProSelect™ is a trademark of Safe Water Technologies, Inc. |

|

|

| |

Features: |

|

| |

• |

Complies with USDA & FDA regulations (paragraph 21 CFR173.25) for potable water applications * |

|

| |

• |

Reversible exchange of organics |

|

| |

• |

Superior physical stability |

|

| |

• |

Certified to NSF/ANSI Standard 61 |

|

|

| * |

Prior to first use for potable water, resin should be backwashed for a minimum of 20 minutes, followed by 10 bed volumes of downflow rinse. |

|

| PHYSICAL PROPERTIES |

| Part Number |

ER20001 |

| Polymer Structure |

Styrene/DVB |

| Functional Group |

Trimethylamine |

| Physical Form |

Spherical beads |

| Resin Color |

Amber |

| Ionic Form (as shipped) |

Chloride |

Total Capacity

Chloride Form |

0.65 meq/mL minimum |

Water Retention

Chloride Form |

70 to 80% |

| Screen Size Distribution |

20 to 50 (U.S. mesh) |

| Fines Content (<50 mesh) |

1% maximum |

| Sphericity |

93% minimum |

| Uniformity Coefficient |

1.6 approximate |

| Approx. Ship. Wt. |

41 lb/cu.ft. |

|

| |

| SUGGESTED OPERATING CONDITIONS |

Max Continuous Temperature

Chloride Form |

170°F (77°C |

| Minimum Bed Depth |

24 inches |

| Pressure Loss (See graph left) |

20 psi maximum |

| Backwash Rate (See graph left) |

25 to 50% |

| Operating pH Range |

4 to 10 SU |

Regenerant Concentration †

Salt Cycle

Optional Hydroxide Addition |

5 to 10% NaCl

0.1 to 0.5% NaOH |

| Regenerant Level |

10 lbs/cu.ft. minimum |

| Regenerant Flow Rate |

0.1 to 0.5 gpm/cu.ft. |

| Regenerant Contact Time |

60 minutes minimum |

| Displacement Flow Rate |

Same as Dilution Flow |

| Displacement Volume |

10 to 15 gal/cu.ft. |

| Rinse Flow Rate |

Same as Service Flow |

| Rinse Volume |

35 to 60 gal/cu.ft. |

Service Flow Rate

Average Flow

Peak Flow |

1 to 2 gpm/cu.ft.

7 gpm/cu.ft. maximum |

|

| NOTE: Physical properties can be certified on a per lot basis, available upon request. |

| |

|

† CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

|

|

| |

|