| APPLICATIONS: |

| • |

Portable Exchange D.I. |

| • |

Condensate Polishing |

| • |

Laboratory and Pharmaceutical |

| • |

Cartridge demineralizers |

| • |

Hemodialysis |

| • |

Boiler Feedwater |

| • |

Chemical and Photographic Solutions |

|

| |

| |

|

| |

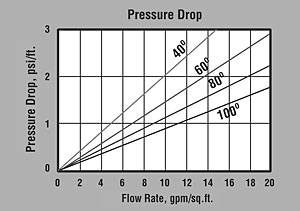

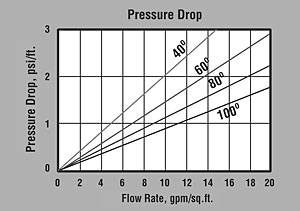

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

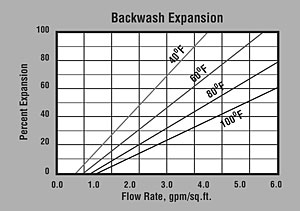

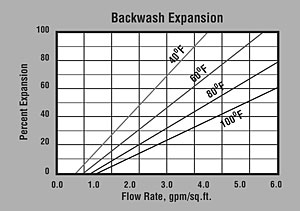

| BACKWASH — The backwash step is used to separate the components prior to regeneration and to remove particles. The separation is optimized at a bed expansion of 50 to 75 percent. |

| |

| |

|

Limitations:

Extended exposure to strong oxidizers (such as chlorine, hydrogen peroxide, and concentrated nitric acid) degrade the structural backbone of the resin and should be avoided.

|

| |

| |

|

CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

| |

| ProBlend™ is a trademark of Safe Water Technologies, Inc. |

|

|

| |

Features: |

|

| |

• |

Conforms to paragraph 21 CFR173.25 of the Food Additives Regulations of the FDA |

|

| |

• |

Designed to provide ultra-high purity water |

|

| |

• |

Highest operating capacity |

|

| |

• |

Low effluent TOC values |

|

| |

• |

Superior thermal and physical stability |

|

| |

• |

Best choice for single use applications, cartridges, & severe operating conditions |

|

|

| |

| PHYSICAL PROPERTIES |

| Part Number |

ER30008 |

Functional Structure

Cation (Hydrogen Form)

Anion (Hydroxyl Form) |

RSO3-H+ (Gel)

R4N+OH- (Type 1 Gel) |

| Physical Form |

Spherical beads |

Screen Size Distribution

+ 16 mesh (US Std.)

– 45 mesh (US Std.) |

2% maximum

2% maximum |

Moisture Content

(as shipped) |

60% maximum |

Volume Ratio (as shipped)

Cation

Anion |

40%

60% |

Total Capacity

Cation (Na+ form)

Anion (Cl- form) |

1.95 meq/mL min.

1.40 meq/mL min. |

| Column Operating Capacity |

0.60 meq/mL (13 Kgrs/cu.ft.) minimum to electrolyte breakthru during initial cycle. |

| Approx. Ship. Wt. |

43 lb/cu.ft. |

| Standard Packaging |

5 or 7 cu.ft. plastic lined fiber drums |

|

| |

| SUGGESTED OPERATING CONDITIONS |

Maximum Temperature

Non-regenerable*

Regenerable |

175°F (80°C)

140°F (60°C) |

| Operating Flow Rate (Typical) |

2 to 10 gpm/cu.ft. |

| pH Range |

0 to 14 |

| Backwash Rate |

See graph left |

| Pressure Drop |

See graph left |

Metals Content (Typical Dry Wt)

Iron (Fe)

Copper (Cu)

Lead (Pb) |

100 ppm maximum

50 ppm maximum

50 ppm maximum |

Percent Conversions to Ionic Form

Cation H

Anion OH

Cl + SO4

CO3 |

99% minimum

90% minimum**

10% maximum

** (see note below) |

|

| * |

6 month typical resin life at 175°F (80°C). |

| ** |

Hydroxides measured in anion component prior to mixing. The CO3 level measured immediately after production is held to the same specifications as the SO4. Actual CO3 levels may change during storage and shipment due to adsorption of CO2 from the atmosphere. We recommend keeping all containers sealed closed until use. For longer storage times, gas barrier packaging (mylar) is suggested. Contact your SWT representative for more information.

|

|

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide

SWT ProBlend High Capacity Resins Comparison Table |

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

|