|

|

| ProSelect™ ER20009 (P/N ER20009) is a high capacity, shock resistant, macroporous, tertiary amine, weakly basic anion resin supplied in the free base form as moist, tough, uniform, spherical beads. ER20009 has tremendous regeneration efficiency and low rinse requirements and is also capable of reversibly adsorbing large organic ions. ER20009 has superior kinetics and greater resistance to oxidation and osmotic shock than standard gel type weak base resins. ER20009 is intended primarily for use in multiple bed demineralizers, resource recovery, and waste treatment applications. ER20009 can be used in multiple bed systems to protect strongly basic resins from fouling while decreasing regenerant consumption. |

| |

| |

| APPLICATIONS: |

Deionization

ER20009 can be used in a two-bed system following a strong acid cation exchanger, such as ProSoft™ Premium, where weak acid ions (silica and carbon dioxide) do not have to be removed. Where complete anionic removal is required, ER20009 can be placed ahead of a strong base anion exchange resin, such as ProSelect™ Silica, where it will efficiently remove strong acids, such as chlorides, sulfates, and nitrates. ER20009 exhibits tremendous regeneration efficiency (90%) and as an added benefit can be regenerated with waste caustic from the strong base anion unit. ER20009 can also be used as the top layer of a stratified anion unit, with ProSelect™ Silica as the bottom layer.

Organics

ER20009 has the ability to reversibly adsorb organic molecules like the naturally occurring humic and tannic acids that are primarily responsible for organic fouling. It can be used in a separate bed, ahead of the strong base exchanger to remove organics and strong acid ions. When used in this scheme ER20009 protects the strongly basic anion exchanger from becoming fouled. |

| |

| |

| NOTE: Click on graphs below to enlarge. |

| |

|

| |

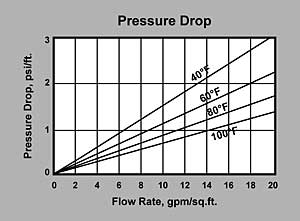

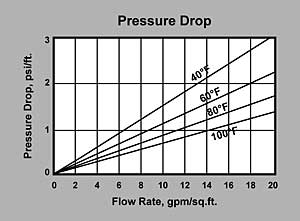

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

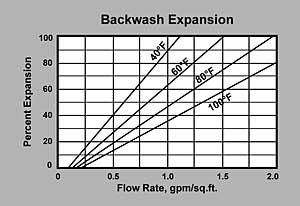

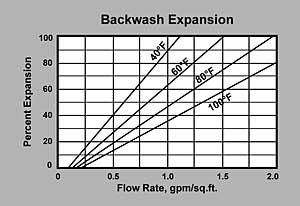

| BACKWASH — After each cycle the resin bed should be backwashed at a rate that expands the bed 50 to 75 percent. This will remove any foreign matter and reclassify the bed. |

| |

|

OPERATING CAPACITY |

|

The operating capacity of ProSelect™ ER20009 for acid removal at various regeneration levels when treating an influent with a concentration of 500 ppm of HCl, as CaCO3, is shown in the following table.

|

| |

Pounds NaOH

per cu.ft. |

Capacity, Kilograins

per cu.ft. |

| 3 |

19.0 |

| 4 |

21.5 |

| 5 |

23.5 |

| 6 |

25.0 |

|

| |

|

Regeneration of ER20009 can be accomplished using sodium hydroxide, ammonium hydroxide, or sodium carbonate.

|

|

|

| |

Features & Benefits: |

|

| |

• |

Organic fouling resistance and high operating capacity |

|

| |

• |

Complies with FDA Regulations (paragraph 21CFR173.25) for Potable Water Applications |

|

| |

• |

Highly uniform particle size, low pressure drop |

|

| |

• |

Superior physical stability |

|

|

| |

| TYPICAL PROPERTIES |

| Part Number |

ER20009 |

| Polymer Structure |

Styrene crosslinked with DVB |

| Functional Group |

R-N-(CH3)2+ |

| Ionic Form (as shipped) |

Free Base |

| Physical Form |

Tough, spherical beads |

Screen Size Distribution

+ 16 mesh (US Std.)

– 50 mesh (US Std.) |

16 to 50

< 5 percent

< 1 percent |

| pH Range |

0 to 14 |

| Sphericity |

> 95 percent |

| Water Retention |

53 to 60 percent |

| Solubility |

Insoluble |

| Approx. Ship. Wt. |

40 lb/cu.ft. |

| Swelling Free Base to Cl- Form |

Approx. 20 percent |

| Total Capacity |

> 1.3 meq/mL |

|

| |

| SUGGESTED OPERATING CONDITIONS |

| Maximum Temperature |

212°F (100°C) |

| Minimum Bed Depth |

24 inches |

| Service Flow Rate |

2 to 4 gpm/cu.ft. |

Backwash Rate

(See graph left) |

50 to 75 percent Bed Expansion |

| Regenerant Concentration * |

1 to 6 percent |

| Regenerant Flow Rate |

0.5 to 1.0 gpm/cu.ft. |

| Regenerant Contact Time |

30 minutes minimum |

| Regenerant Level |

3 to 6 lb/cu.ft. |

| Displacement Rinse Rate |

Same as Regenerant Flow Rate |

| Displacement Rinse Volume |

10 to 15 gal/cu.ft. |

| Fast Rinse Rate |

Same as Service Flow Rate |

| Fast Rinse Volume |

35 to 60 gal/cu.ft. |

|

| |

| |

|

* CAUTION: DO NOT MIX ION EXCHANGE RESINS WITH STRONG OXIDIZING AGENTS. Nitric acid and other strong oxidizing agents can cause explosive reactions when mixed with organic materials such as ion exchange resins.

|

| |

ADDITIONAL INFORMATION:

SWT Ion Exchange Resin Guide |

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

| |

| |

| ProSelect™ is a trademark of Safe Water Technologies, Inc. |

|

|

| |

|