|

Back to SWT Home Page

| Back to SWT News Index

|

|

|

|

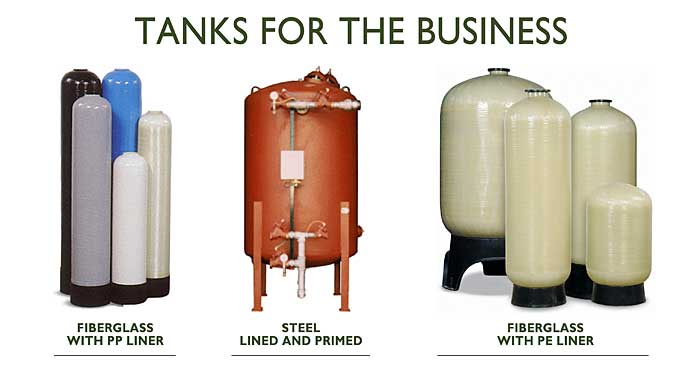

COMPOSITE PRESSURE TANKS

Fiberglass Wrapped with Polypropylene Liner

Residential / Light Commercial

*Click Here for Detailed Specifications

|

| • |

Wound with continuous premium fiberglass to provide superior strength under pressure |

| • |

Custom formulated co-polymer polypropylene inner shell provides superior elasticity and impact resistance |

| • |

Extruded side wall produces consistent wall thickness and eliminates potential thin spots or stress points |

| • |

Base is injection molded from impact/temperature resistant polypropylene |

| • |

Glass-filled threaded inlet is mechanically and chemically welded to the dome to eliminate leak paths |

| • |

4 inch stainless steel inlet virtually eliminates cross threading |

| • |

150 psi maximum operating pressure |

| • |

120 degrees F maximum operating temperature |

| • |

Certified to NSF/ANSI Standard 44 |

| • |

Available in natural, almond, blue, black, gray |

| • |

Made in the USA |

|

|

|

|

|

|

|

|

COMPOSITE PRESSURE TANKS

Fiberglass Wrapped with Polyethylene Liner

Residential / Commercial / Industrial

*Click Here for Detailed Specifications

|

| • |

Inner shell constructed of high molecular weight polyethylene |

| • |

Wound with continuous fiberglass to provide superior strength under pressure |

| • |

Integrally molded threaded and flanged inlets offer leak-free performance |

| • |

100% corrosion-free |

| • |

150 psi maximum operating pressure |

| • |

Threaded tanks: 120 degrees F maximum operating temperature

Flanged tanks: 150 degrees F maximum operating temperature |

| • |

6 to 16 inch tanks Certified to NSF/ANSI Standard 44

18 to 63 inch tanks Certified to NSF/ANSI Standard 61 |

| • |

Available in natural, almond, blue, black, gray |

| • |

Private labeling available |

| • |

ASME coded available |

| • |

Made in the USA |

|

|

|

|

|

|

|

|

STEEL TANKS

Lined and Primed

Commercial / Industrial

*Click Here for Detailed Specifications

|

| • |

Meets all requirements for both FDA and US Department of Agriculture |

| • |

ASME Code and Non-Code tanks available |

| • |

Durable, rust-proofed, and built to last |

| • |

Certified to NSF/ANSI Standard 61 |

| • |

Epoxy lined and primed with NSF/ANSI Standard 61 Certified lining |

| • |

100 psi maximum operating pressure |

| • |

140 degrees F maximum operating temperature |

| • |

Hydrostatically tested to 130% of its design pressure |

| • |

Standardized tanks ranging from 20 to 72 inch diameter |

| • |

Standardized equipment means faster shipping |

| • |

New Steel Tanks Configuration Worksheet available for download |

| • |

Custom designs available |

| • |

Made in the USA |

|

|

|

|

|

|

|

|

SAFE WATER TECHNOLOGIES, INC.

996 Bluff City Blvd.

Elgin, IL 60120 USA

Tel: 847.888.6900 / Fax: 847.888.6924

Email: info@swtwater.com

Web: www.swtwater.com

To subscribe to SWT Enews, click here.

Copyright 2012-2020, Safe Water Technologies, Inc.

|