Arsenic Removal

Inorganic arsenic (arseniite and arsenate) can be removed by MetalEase-ALF. The process is very pH sensitive and capacity decreases rapidly when the pH is below 5.5 or above 6.0. Arsenite is not removed nearly as well as arsenate; therefore, prechlorination to convert arsenite to arsenate may be required. Arsenic removal is also affected by temperature and by the TDS of the feedwater. Increasing temperature increases capacity while increasing TDS decreases capacity.

Equilibrium capacity for arsenate (1,000 ppm TDS, 25°C, 1 mg/L As) is approximately 0.66 lbs/cu.ft. Operating capacity to a 10% leakage end point is approximately 10% of the equilibrium capacity. Regeneration can be accomplished by using 3 to 4 lbs/cu.ft. of 2 to 4% sodium hydroxide, over 20 to 30 minutes, followed by nuetralization with acid to a pH of 5 to 6.

Lead Removal

Dissolved lead is adsorbed by MetalEase-ALF and is not normally regenerable. Capacity for lead is at least 0.4 lbs/cu.ft. while maintaining greater than 98% lead removal. This process is not dramatically affected by flow rate, temperature, or TDS. However, pH should be maintained above 6.0 as lead removal drops under acidic conditions, and below 10 as lead precipitates under basic conditions.

Fluoride Removal

Fluoride is removed by MetalEase-ALF by a chemical reaction with the media. The process is flow and pH sensitive. The best results are obtained when the flow is limited to about 1 gpm/cu.ft. and the pH is held at 5.5. Higher flows and higher or lower pH causes a significant loss of capacity. The best capacity obtainable is approximately 0.2 lbs/cu.ft. Leakage of fluoride is generally less than 0.1 mg/L to breakthrough.

Regeneration can be accomplished using 3 to 4 lbs/cu.ft. of 2 to 4% sodium hydroxide over 20 to 30 minutes, followed by neutralization with acid to a pH of 5 to 6.

|

| |

| |

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

| |

| |

Warning

For safety and handling purposes, avoid contact with eyes, skin, and clothing. Avoid breathing the dust and always use adequate ventilation. Wash thoroughly after handling. Keep away from heat and easily oxidizable materials. |

| |

| |

| MetalEase-ALF™ is a trademark of Safe Water Technologies, Inc. |

|

|

| |

Features & Benefits: |

|

| |

• |

Does not release arsenic, lead, or fluoride except during regeneration and can be sent to landfill when used in single pass applications (ie. cartridges, exchange tanks, rebedding, etc.) |

|

| |

• |

Removes metals through a combination of adsorption and chemical reaction with the media, thus the removal is not dependent on ion exchange |

|

| |

• |

Uniform particle size with minimal shrinkage or swelling and low pressure loss |

|

| |

• |

Physically stable and can be used over a wide pH range |

|

| |

• |

Certified to NSF/ANSI Standard 61 for drinking water applications |

|

|

| |

| TYPICAL PROPERTIES |

| Part Number |

METALEASE ALF |

| Chemical Structure |

Crystalline Aluminum Oxide |

| Active Ingredients |

92% minimum |

| Alumina (Al2O3) |

93% wt |

| Sodium Oxide (Na2O) |

0.3% wt |

| Iron Oxide (Fe2O3) |

0.02% wt |

| Titanium Dioxide (TiO2) |

0.002% wt |

| Silica (SiO2) |

0.02% wt |

| Physical Form |

Tough Uniform Granules |

| Color |

White |

| Surface Area |

315 to 330 m²/gr |

| Mesh Size |

28 x 48 |

| pH Range |

4 to 10 |

| Water Retention |

Less than 5% |

| Solubility |

Nil |

| Net Weight |

47 to 48 lbs/cu.ft. |

| Shipping Weight |

50 lbs/cu.ft. |

| Packaging |

1 cu.ft. box or

37 cu.ft. supersack |

|

| |

| SUGGESTED OPERATING CONDITIONS |

| Max. Temperature |

100°C (212°F) |

| Max. Free Chlorine |

1 ppm |

| Min. Bed Depth |

36 inch minimum

(5 to 7 foot preferred) |

| Backwash Rate |

To achieve 10 to 25% expansion |

| Continuous Flow Rate |

1 to 2 gpm/cu.ft. |

| Intermittent Flow Rate |

1 to 5 gpm/cu.ft. |

|

ADDITIONAL INFORMATION:

SWT Filtration Media Guide

Iron Removal Comparison Chart

|

| |

| |

|

| |

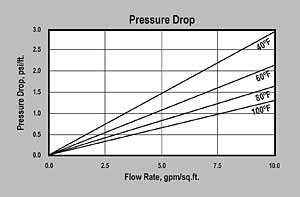

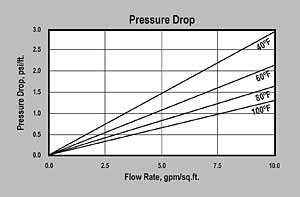

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

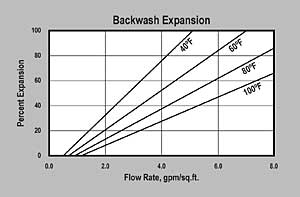

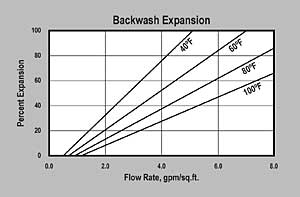

| BACKWASH — The graph above shows the expansion characteristics as a function of flow rate at various temperatures. |

| |

|