In ground waters, the dissolved iron is usually in the ferrous bicarbonate state due to the excess of free carbon dioxide and is not filterable. Birm, acting as a catalyst between the oxygen and the soluble iron compounds, enhances the oxidation reaction of Fe++ to Fe+++ and produces ferric hydroxide which precipitates and may be easily filtered.

The physical characteristics of Birm provide an excellent filter media which is easily cleaned by backwashing to remove the precipitant. Birm is not consumed in the iron removal operation and therefore offers a tremendous economic advantage over many other iron removal methods. |

| |

| |

|

| |

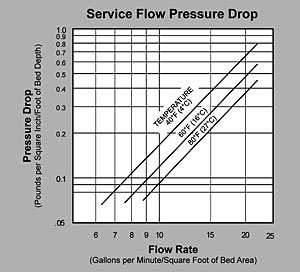

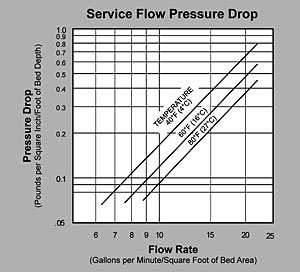

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

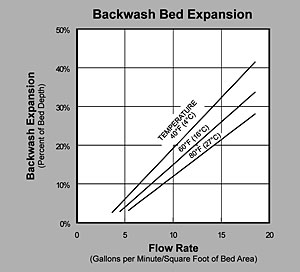

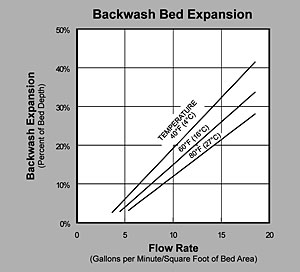

| BACKWASH — After each cycle the media bed should be backwashed at a rate that expands the bed 20 to 40 percent. |

| |

| |

When using Birm for iron removal, it is necessary that the water: contain no oil or hydrogen sulfide, organic matter not to exceed 4 to 5 ppm, the dissolved oxygen content equal at least 15% of the iron content with a pH of 6.8 or more. If the influent water has a pH of less that 6.8, neutralizing additives such as SWT Neutralizing Medias (P/N PH10001 or P/N PH10003) or soda ash may be used prior to the Birm filter to raise the pH. A water having a low dissolved oxygen level may be pretreated by aeration.

Additions of chemicals to influent or backwash water which contacts Birm media may inhibit iron or manganese removal or may break down or coat Birm media. Chlorination greatly reduces Birm’s activity. High concentrations of chlorine compounds may deplete the catalytic coating. Polyphosphates are known to coat Birm and reduce Birm’s ability to remove iron or manganese. Before adding any chemical to the influent or backwash water, the chemical’s compatibility with Birm should be thoroughly tested.

Birm media may also be used for manganese reduction with the same dependability as iron removal. In these applications the water to be treated should have a pH of 8.0 to 9.0 for best results. If the water also contains iron, the pH should be below 8.5. High pH conditions may cause the formulation of colloidal iron which is very difficult to filter out. All other conditions remain the same for either manganese or iron removal. |

|

|

| |

Features: |

|

| |

• |

No chemicals needed for maintenance when used under proper conditions. Regeneration is not required. |

|

| |

• |

Iron removal efficiency is extrememly high. |

|

| |

• |

Negligible labor cost — only periodic backwashing is required. |

|

| |

• |

Durable material with a long life and a wide temperature range. |

|

| |

• |

Certified to NSF/ANSI Standard 61 |

|

|

| |

| |

| TYPICAL PROPERTIES |

| Part Number |

LC10001 |

| Color |

Black |

| Specific Gravity |

2.0 gm/cc |

| Effective Size |

0.48 mm |

| Uniformity Coefficient |

2.7 |

| Mesh Size |

10 x 40 |

| Net Weight |

35 to 40 lb / cu.ft. |

| Packaging |

1 cu.ft. bag |

|

| |

| SUGGESTED OPERATING CONDITIONS |

| Alkalinity |

2 times the combined sulfate and chloride concentration minimum |

| Water pH Range |

6.8 to 9.0 |

| Dissolved Oxygen |

15% of the iron (or iron and manganese) content minimum |

| Water Temperature |

100°F (38°C) maximum |

| Bed Depth |

30 to 36 inches |

| Freeboard |

50% minimum |

| Service Flow Rate |

3.5 to 5 gpm/sq.ft. intermittent (favorable local conditions may allow higher) |

| Backwash Flow Rate |

10 to 12 gpm/sq.ft. @ 60ºF |

| Backwash Bed Expansion |

20 to 40% of bed depth min. |

|

| |

| INFLUENT AND BACKWASH LIMITATIONS |

| Free Chlorine |

0.5 ppm maximum |

| Hydrogen Sulfide |

Should be removed prior to contact with Birm |

| Oil |

None present |

| Polyphosphates |

None present |

|

ADDITIONAL INFORMATION:

SWT Filtration Media Guide

Iron Removal Comparison Chart

|

| |

|

| Certified to NSF/ANSI Standard 61 |

|

| |

| |

|

California Proposition 65 Warning

This product contains crystalline silica which is known to the State of California to cause cancer and other substances which are known to the State of California to cause cancer, birth defects, and reproductive harm.

|

| |

| |

|

This filter media does not remove or kill bacteria. Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

|

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

| |

| |

| Birm® is a registered trademark of Clack Corporation. |

|