| APPLICATIONS: |

| • |

Bottle water and drinking water plants |

| • |

Economical pre-filter for RO systems |

| • |

Well water and industrial wastewater filtration |

| • |

Cooling tower, chillers, heat exchanger water filtration |

|

| |

| |

| Physical filtration barriers for accumulation or collection of microorganisms in water that endanger human health have been in focus during the last several years. Zeolite-61 will be an ideal collector of pathogens such as Giardia, cryptosporidium, and other oocyst and protozoa and their spores. Most of these organisms and their spores are in the size range of 0.5 to 10 micrometers (microns). In contrast, the water permeable pores in Zeolite-61 are mostly smaller than 0.05 microns; therefore the zeolite fragment or granule can surface collect a high percentage of these microorganisms while the water passes through the zeolite fragment. The U.S. drinking water standards for microorganism pathogens and turbidity can be easily met using a natural, low-cost material, such as Zeolite-61 rather than sand which is chiefly quartz grains. |

| |

| US STANDARD MESH SIZE |

| US MESH |

% RETAINED |

| +14 |

1.6 |

| +20 |

59.2 |

| +30 |

30.1 |

| +40 |

6.9 |

| –40 |

2.2 |

|

| |

| This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification. |

| |

| |

|

| |

Zeolite-61 vs. Conventional Media Performance

(Pressure Vessels) |

| Filter Media |

Filter Rating

(nominal) |

Solids Loading Capacity |

| Sand (20 x 40 Mesh) |

~20 micron |

1x |

Sand/Anthracite

(20 x 40 Mesh & Anthracite) |

~15 micron |

~1.4x |

Multimedia

(8 x 12 Garnet, 30 x 40 Garnet, 0.45–0.55 Sand, Anthracite #1) |

~12 micron |

~1.6x |

| Zeolite-61 (14 x 40 Mesh) |

<5 micron |

~2.7x |

| |

| The examples below illustrate the advantages of Zeolite-61 by comparing two systems designed for the same service flow; one system based on Zeolite-61, and one multimedia system (gravel, garnet, fine garnet, anthracite) Each system is based on best design practices for the respective media. |

| |

| EXAMPLE 1: 15 gpm Service Flow |

| |

Zeolite-61 |

Multimedia |

|

| Surface Loading |

15 gpm/sq ft |

5 gpm/sq ft |

| Surface Area Required |

1.0 sq ft |

3.0 sq ft |

| Tank Dimensions |

14 x 65 inch |

24 x 72 inch |

Media Volume Required

(with underbedding) |

3.7 cu ft |

10.8 cu ft |

Media Weight

(with underbedding) |

216 lb |

1,057 lb |

Backwash Flow Required

@ 60ºF |

17 gpm |

51 gpm |

| Daily Backwash Volume |

179 gallons |

510 gallons |

| Filtration |

<5 micron |

<10 micron |

| Ion Exchange Capacity |

1.5–1.8 meq/g |

None |

| Comparative Cost |

1x |

3x |

| |

|

|

| EXAMPLE 1: 45 gpm Service Flow |

| |

Zeolite-61 |

Multimedia |

| Surface Loading |

15 gpm/sq ft |

5 gpm/sq ft |

| Surface Area Required |

3.0 sq ft |

9.0 sq ft |

| Tank Dimensions |

24 x 72 inch |

42 x 72 inch |

Media Volume Required

(with underbedding) |

11 cu ft |

35.3 cu ft |

Media Weight

(with underbedding) |

672 lb |

3,469 lb |

Backwash Flow Required

@ 60ºF |

53 gpm |

153 gpm |

| Daily Backwash Volume |

556 gallons |

1,530 gallons |

| Filtration |

<5 micron |

<10 micron |

| Ion Exchange Capacity |

1.5–1.8 meq/g |

None |

| Comparative Cost |

1x |

3.3x |

| |

|

|

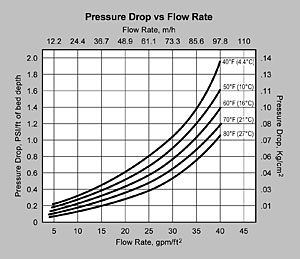

| Typical Backwash Flow Requirements |

| Water Tempersature |

Backwash Flow Rate* |

| gpm/sq.ft. |

m/h |

| 40ºF (4.5ºC) |

12.5 |

30.6 |

| 50ºF (10ºC) |

14.8 |

36.2 |

| 60ºF (16ºC) |

17.2 |

42.0 |

| 70ºF (21ºC) |

19.8 |

48.4 |

| 80ºF (27ºC) |

22.3 |

54.5 |

|

| * 40% bed expansion for 50% freeboard. |