| • |

All components can be serviced while the valve is inline |

| • |

Separate flow and control chambers permit positive closing without springs |

| • |

Reinforced diaphragms are pre-formed and stress relieved to maximize responsiveness and product life |

| • |

Diaphragm acts as an actuator, eliminating the need for electric or pneumatic actuators |

| • |

All internal parts in contact with media are made of composite materials * |

| • |

Seals are ethylene propylene for better chemical resistance ** |

| • |

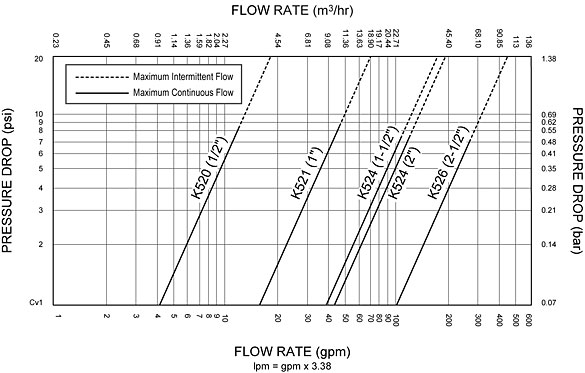

Available in sizes from 1/2 to 2-1/2 inch |

| • |

A variety of end connectors are available to make the valve compatible in pipe sizes from 3/8 to 3 inch |

| • |

Adaptable to a wide variety of control devices |