| • |

All components can be serviced while the valve is inline |

| • |

Separate flow and control chambers permit positive closing without springs; and only nominal cost for spring assist opening for low-pressure and self-draining applications |

| • |

Reinforced diaphragms are pre-formed and stress relieved to maximize responsiveness and product life |

| • |

Diaphragm acts as an actuator, eliminating the need for electric or pneumatic actuators |

| • |

All internal parts in contact with media are made of composite materials * |

| • |

Seals are ethylene propylene for better chemical resistance ** |

| • |

Two dynamic o-rings on the shaft, with a vent in between the o-rings, to prevent damage to the diaphragm |

| • |

Female socket weld connectors for easy installation and the ability to remove the valve without disrupting the service piping |

| • |

Valve bodies provided with molded pads that can be used to support the piping manifold |

| • |

Cap held by a retaining ring, eliminating screws and nuts |

| • |

No external metal parts to corrode in aggressive atmosphere |

| • |

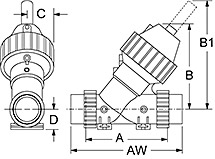

Available in sizes from 1 to 3 inch |

| • |

Avariety of end connectors are available to make the valve compatible in pipe sizes from 3/4 to 3 inch |

| • |

Adaptable to a wide variety of control devices |

| • |

Can be actuated with either air or water as control fluid |