| • |

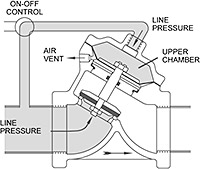

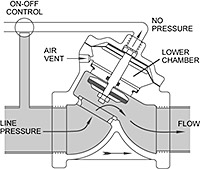

Larger diaphragm area than seat area permits drip-tight closing without any springs |

| • |

All components can be serviced while the valve is inline |

| • |

Separate flow and control chambers permit positive closing without springs |

| • |

Reinforced diaphragms are pre-formed and stress relieved to maximize responsiveness and product life |

| • |

Diaphragm acts as an actuator, eliminating the need for electric or pneumatic actuators |

| • |

Cast iron, brass, stainless steel, and nitrile elastomer components for unparalleled service |

| • |

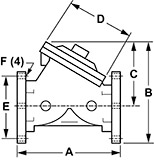

Available in 3/4 to 3 inch threaded (NPT or BSP) and 3 to 6 inch flange drilled in accordance with ASA 16.1 class 125, or BSP4504 |

| • |

Adaptable to a wide variety of control devices |