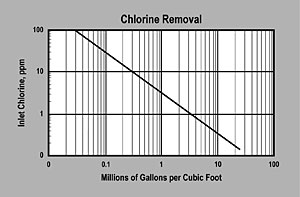

| SWT's ProActive Acid Washed 12 x 40 Granular Activated Carbon (IT50005) can be expected to remove a minimum of one pound of chlorine per pound of carbon. A 24 inch deep bed of IT50005 will reduce 1 ppm of inlet chlorine to below the limit of detection. |

| Removal of organics by activated carbon is variable and is site specific. In general, large organic molecules are removed more completely than smaller molecules. The probable mechanism of removal is adsorption into the carbon pores. Organics with fewer than 6 carbon atoms are not well removed. Aromatic organic molecules are generally removed better than aliphatic molecules . Organic ions are generally not well removed. Polar molecules are not removed as well as non-polar molecules. |

| IT50005 can be regenerated with steam to remove organics and/or chlorine that has been adsorbed. Contact your representative for additional information. |