|

|

|

Water’s Edge™ Distributor System Kits are custom tailored to meet

your specific application needs. Our design engineering expertise and more than 30 years experience ensure that you get the

best distribution solution available. |

| |

|

|

|

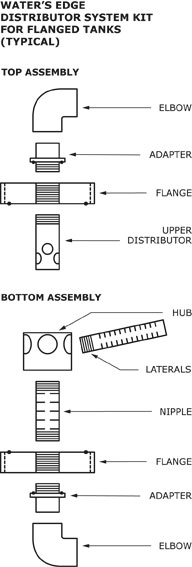

SWT’s Water’s Edge Distributor System Kits for Flanged

Tanks are fabricated from non-corrosive FDA and NSF approved materials for use in softeners,

dealkalizers, carbon filters, sediment filters, iron filters, and multimedia filters. They are recommended

for use with Aquamatic-style valve nests and side-mounted valves or simple flow-through filtration.

Water’s Edge Distributor Systems are extra strong and durable for use with heavy filtration medias (gravel,

sand, garnet) and can be used with a variety of regenerants including salt, caustics, acids, chlorine, etc.

The collection screens (laterals) have 0.010 standard slotting for use with 50 mesh filter media or larger.

They are designed to spread flow evenly across the filter bed to eliminate

dead zones and to provide proper and

even lift and separation during backwash. |

| |

| Technical Specifications |

| Max. Recommended Operating Temperature: 140°F (60°C) |

| Max Recommended Operating Pressure: 150 psi |

| ΔP @ 5 ft./sec. Velocity: ≤ 3 psi |

| Standard Materials of Construction: PVC, EPDM |

Available Materials of Construction: CPVC, Polypropylene, PVDF, PTFE,

HDPE, ABS, Nylon, Acetal, etc. |

Slot Widths (for as small as 70 mesh media):

0.008 inch (0.203 mm)

0.010 inch (0.254 mm) – Standard

0.012 inch (0.305 mm)

0.016 inch (0.406 mm)

0.020 inch (0.508 mm)

0.032 inch (0.813 mm)

0.125 inch (3.175 mm) |

|

|

|

| |

| |

| Features and Benefits |

| • |

Fabricated from non-corrosive FDA and NSF approved materials |

| • |

Flow rates up to 300 gpm available |

| • |

Flow patterns from 3.5 to 20 gpm/sq.ft. |

| • |

Resistant to brine, acid, caustics, chlorine, chloramine, bacteria, oxidation |

| • |

Solid bar stock and Schedule 80 pipe construction ensures maximum reliability |

| • |

Ideal for use in softeners, dealkalizers, GAC, sediment, iron & multimedia filters |

| • |

Available for tanks from 18 to 63 inch diameter |

| • |

Customizing available |

| • |

Designed to spread flow evenly across the filter bed to eliminate dead zones |

| • |

Provides proper and even lift and separation during backwash |

|

| |

| |

|

Water’s Edge DS Kits for Flanged Tanks — Common Assemblies |

MODEL

NUMBER |

TANK SIZE

INCHES |

PIPE SIZE

INCHES |

LATERALS

NUMBER (SIZE) |

| SM-DSF1815 |

18 x 65 |

1.5 |

6 (3/4 inch) |

| SM-DSF2115 |

21 x 62 |

1.5 |

8 (3/4 inch) |

| SM-DSF2415 |

24 x 65 |

1.5 |

8 (3/4 inch) |

| SM-DSF242 |

24 x 72 |

2 |

8 (3/4 inch) |

| SM-DSF302 |

30 x 72 |

2 |

12 (3/4 inch) |

| SM-DSF3025 |

30 x 72 |

2.5 |

12 (3/4 inch) |

| SM-DSF362 |

36 x 72 |

2 |

12 (3/4 inch) |

| SM-DSF3625 |

36 x 72 |

2.5 |

12 (3/4 inch) |

| SM-DSF422 |

42 x 72 |

2 |

16 (1 inch) |

| SM-DSF4225 |

42 x 72 |

2.5 |

16 (1 inch) |

| SM-DSF423 |

42 x 72 |

3 |

16 (1 inch) |

| SM-DSF482 |

48 x 72 |

2 |

16 (1 inch) |

| SM-DSF4825 |

48 x 72 |

2.5 |

16 (1 inch) |

| SM-DSF483 |

48 x 72 |

3 |

16 (1 inch) |

| SM-DSF484 |

48 x 72 |

4 |

16 (1 inch) |

| SM-DSF633 |

63 x 86 |

3 |

20 (1 to 1.25 inch) |

| SM-DSF634 |

63 x 86 |

4 |

20 (1 to 1.25 inch) |

| SM-DSF634-CUSTOM |

63 x 86 |

4 |

21 (1 inch) |

|

| |

| Custom sizes, configurations, and materials are our specialty. Contact SWT with your requirements. |

| |

|