|

|

|

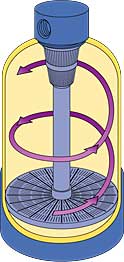

| The Cyclonic Distributor System™ (CDS) is an innovative vessel technology providing higher flow rates, less pressure loss, improved treatment capacity, product flexibility, and water conservation. Simply put—Smart technology. The CDS creates uniform water distribution in both service and regeneration flow paths to better utilize media surface area and depth, which extends the contaminant removal capacity of the media and subsequently requires less regeneration. Mid plates are available to compartmentalize several different media in a single vessel—eliminating the need for multiple tank systems, reducing system costs, and providing easier installations and servicability. |

| |

| BENEFITS |

| • |

Conserves water |

| • |

Softeners require less salt |

| • |

30% less backwashing |

| • |

Increased resin capacity of 10 to 15% compared to standard basket distribution systems |

| • |

Up to 40% less pressure drop through the system |

| • |

Spin-welded plate to inner bottom dome designed to handle over 6500 lbs. of force and differential pressure |

| • |

No gravel underbed saves on overall cost and unit weight |

| • |

Permanent attachment of the riser tube and distribution plates eliminates rebedding when servicing the valve |

| • |

100% corrosion-free |

| • |

Reduces environmental impact |

| • |

Creates cleaner, more efficient water treatment systems |

|

|

| OPERATING PARAMETERS |

| • |

150 psi maximum operating pressure |

| • |

120ºF (50ºC) maximum operating temperature |

|

| DESIGN PARAMETERS |

| • |

250,000+ cycles, ambient and hot 150ºF (66ºC), 0 to 150 psi without leakage |

| • |

4:1 Safety Factor (600 psi minimum burst) |

| • |

Stress Rupture: 1000 hours minimum at 150ºF (66ºC) and 150 psi static pressure |

|

|

| |

| Compare Standard Basket Distributor Flow Paths to the Cyclonic Distributor System™ |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

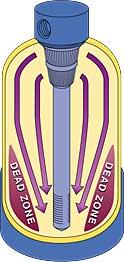

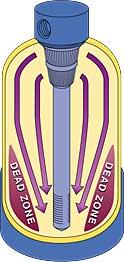

Standard Service

leaves "dead zones" of

unused media in the

bed and promotes

channeling. |

|

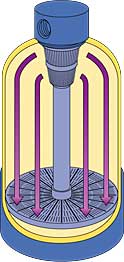

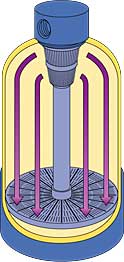

Cyclonic Service

utilizes the entire

media bed. |

|

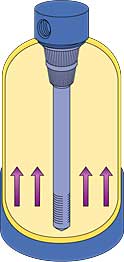

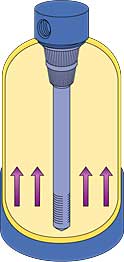

Standard Backwash

lifts the bed. |

|

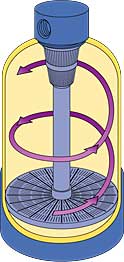

Cyclonic Backwash

utilizes angled plate

slots to expand the

full bed and swirl

the media, resulting in

a more vigorous and

effective cleaning of

the entire media bed. |

| |

|

|

|

|

|

|

|

| |

| CDS VS. STANDARD BASKET DISTRIBUTORS |

| (Comparing tanks with one cubic foot of 10 percent resin.) |

| CDS Tank |

Standard Tank |

| Bed expansion in backwash 10.5 inches of lift |

Bed expansion in backwash 5 inches of lift |

Time to lift bed to full expansion

at 2.0 gpm = 2.0 minutes |

Time to lift bed to full expansion

at 2.0 gpm = 4.25 minutes |

| Four minute backwash time = 8.0 gal. |

Eight minute backwash time = 16.0 gal. |

Fast rinse reduced from six to two minutes

at 2.0 gpm = 4.0 gal. |

Fast rinse had to stay at six minutes

at 2.0 gpm = 12.0 gal. |

|

| |

| BACKWASH TESTING RESULTS OF A 16x65 CDS CARBON SYSTEM |

| "Sweet Spot" for backwash is 5.76 gpm/sq.ft. |

| Standard specification is 8 to 10 gpm. |

| Volume savings and fluidization time with full expansion of bed is less than 2 minutes. |

| CDS backwashes for 7 to 8 minutes (compared to typical carbon filters of 14 minutes or more). |

| |

| CDS THIRD-PARTY VALIDATION AND TESTING RESULTS |

| (WQA/NSF 44 comparison testing of a one cubic foot softener) |

| Capacity Test @ 4.5 lbs. of salt |

| Standard tank with gravel = 3472 grains |

| CDS = 4333 grains |

| Increase of 25% |

| |

| Gallons to Drain |

| Cone and gravel = 53.7 |

| CDS = 31 |

| Decrease of 42% |

| |

| Pressures/Delta P |

| Cone and gravel = 13.4 gpm @ 15psig Delta P |

| CDS = 13.4 gpm @ 9.8psig Delta P |

| Increase of 25% |

| CDS @ 15psig Delta P, Flow rate is 17.8 gpm |

| Equals a 33% increase in flow rate |

| |

| CALIFORNIA PROPOSITION 65 |

|

WARNING: This product can expose you to chemicals including Sulfuric Acid which is known to the State of California to cause cancer and/or birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov. |

|

|

| |

|

All CDS pressure vessels are wound fiberglass composite tanks with copolymer polypropylene liner and are NSF® listed. 100% made in USA.

|

| |

| CYCLONIC DISTRIBUTOR SYSTEM BOTTOM PLATES |

| Available for 7, 8, 9, 10, 12, 13, 14, and 16 inch diameter tanks. See tables below for tank details. |

| Bottom Plate Riser Tube Adapters Available: |

| – |

1.050 Adapter for 1 inch Valves |

| – |

1.050 Adapter for 1 inch Valves — For Bottom Opening Stacked Tank Systems |

| – |

32mm Adapter for 32mm Valves |

| – |

1.315 Adapter for 1.25 inch Valves |

| – |

2.375 Adapter for 2 inch Valves and 16 inch CDS |

| |

|

| CYCLONIC DISTRIBUTOR SYSTEM MID PLATES |

| Available for 10 and 13 inch diameter tanks. See tables below for tank details. |

| – |

One (1) Mid Plate |

| – |

Two (2) Mid Plates |

| – |

Three (3) Mid Plates — No Bottom Plate, only available with Dual Inlet Bottom Opening Vessels |

| – |

Four (4) Mid Plates — No Bottom Plate, only available with Dual Inlet Bottom Opening Vessels |

| Mid Plate Riser Tube Adapters Available: |

| – |

1.050 Adapter for 1 inch Valves — For upper plate location of One Mid Plate Systems |

| – |

1.050 Adapter for 1 inch Valves — For lower plate location of Two Mid Plate Systems |

| – |

1.315 Adapter for 1.25 inch Valves — For upper plate location of One Mid Plate Systems |

| – |

1.315 Adapter for 1.25 inch Valves — For lower plate location of Two Mid Plate Systems |

| Mid Plate Accessories Available: |

| – |

Mid Plate Fill Tube Assembly |

| – |

Mid Plate Center Adapter Installation and Removal Tool |

| – |

Mid Plate Media Removal Tool |

| |

|

| CYCLONIC DISTRIBUTOR SYSTEM RISER PIPE DIAMETERS |

| 7 thru 14 inch Diameter Tanks: |

| – |

3/4 inch |

| – |

32mm (bottom only) |

| – |

1 inch |

| 16 inch Diameter Tanks: |

| – |

up to 2 inch |

|

| |

| |

| 7 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE0714C20* |

7 x 14 |

2.5 |

Standard |

0.24 |

14.6 (371) |

4 (1.8) |

50 |

| NE0724C20* |

7 x 24 |

2.5 |

Standard |

0.45 |

23.6 (599) |

5 (2.3) |

24 |

| NE0730C20* |

7 x 30 |

2.5 |

Standard |

0.59 |

30.4 (772) |

5 (2.3) |

24 |

| NE0735C20* |

7 x 35 |

2.5 |

Standard |

0.67 |

34.9 (886) |

6 (2.7) |

24 |

| NE0744C20* |

7 x 44 |

2.5 |

Standard |

0.87 |

44.2 (1123) |

7 (3.2) |

24 |

|

| |

| 8 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE0818C20* |

8 x 18 |

2.5 |

Standard |

0.43 |

18.4 (467) |

5 (2.3) |

28 |

| NE0824C20* |

8 x 24 |

2.5 |

Standard |

0.57 |

23.5 (597) |

5 (2.3) |

32 |

| NE0830C20* |

8 x 30 |

2.5 |

Standard |

0.76 |

29.9 (759) |

6 (2.7) |

18 |

| NE0835C20* |

8 x 35 |

2.5 |

Standard |

0.88 |

34.9 (886) |

7 (3.2) |

18 |

| NE0840C20* |

8 x 40 |

2.5 |

Standard |

1.02 |

39.8 (1011) |

8 (3.6) |

18 |

| NE0844C20* |

8 x 44 |

2.5 |

Standard |

1.14 |

44.2 (1123) |

8 (3.6) |

18 |

|

| |

| 9 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE0918C20* |

9 x 18 |

2.5 |

Standard |

0.53 |

18.4 (470) |

5 (2.3) |

28 |

| NE0935C20* |

9 x 35 |

2.5 |

Standard |

1.11 |

34.8 (884) |

9 (4.1) |

18 |

| NE0940C20* |

9 x 40 |

2.5 |

Standard |

1.31 |

40.3 (1024) |

9 (4.1) |

14 |

| NE0942C20* |

9 x 42 |

2.5 |

Standard |

1.38 |

42.3 (1074) |

10 (4.5) |

16 |

| NE0948C20* |

9 x 48 |

2.5 |

Standard |

1.59 |

48.3 (1227) |

11 (5.0) |

16 |

|

| |

| 10 INCH DIAMETER TANKS |

For Bottom Plate substitute "U" for "C" in Part Number;

For Mid Plates substitute "V" for "C" in Part Number;

For Bottom and Mid Plates substitute "X" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE1018C20* |

10 x 18 |

2.5 |

Standard |

0.64 |

18.5 (470) |

6 (2.7) |

48 |

| NE1022C20* |

10 x 22 |

2.5 |

Standard |

0.79 |

22.0 (559) |

7 (3.2) |

32 |

| NE1024C20* |

10 x 24 |

2.5 |

Standard |

0.88 |

23.7 (602) |

7 (3.2) |

32 |

| NE1030C20* |

10 x 30 |

2.5 |

Standard |

1.15 |

30.0 (762) |

9 (4.1) |

12 |

| NE1035C20* |

10 x 35 |

2.5 |

Standard |

1.38 |

35.0 (889) |

10 (4.5) |

12 |

| NE1040C20* |

10 x 40 |

2.5 |

Standard |

1.62 |

40.6 (1031) |

11 (5.0) |

12 |

| NE1044C20* |

10 x 44 |

2.5 |

Standard |

1.78 |

44.3 (1125) |

12 (5.4) |

12 |

| NE1047C20* |

10 x 47 |

2.5 |

Standard |

1.90 |

47.2 (1199) |

12 (5.4) |

14 |

| NE1054C20* |

10 x 54 |

2.5 |

Standard |

2.21 |

54.4 (1382) |

14 (6.4) |

16** |

| NE1060C20* |

10 x 60 |

2.5 |

Standard |

2.50 |

60.6 (1539) |

15 (6.8) |

1 |

| NE1065C20* |

10 x 65 |

2.5 |

Standard |

2.69 |

65.1 (1654) |

16 (7.3) |

1 |

|

| |

| 12 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE1229C20* |

12 x 29 |

2.5 |

Standard |

1.62 |

29.5 (749) |

11 (5.0) |

9 |

| NE1229C40* |

12 x 29 |

4.0† |

Standard |

1.62 |

29.5 (749) |

11 (5.0) |

9 |

| NE1236C20* |

12 x 36 |

2.5 |

Standard |

2.02 |

36.3 (922) |

13 (5.9) |

9 |

| NE1236C40* |

12 x 36 |

4.0† |

Standard |

2.02 |

36.3 (922) |

13 (5.9) |

9 |

| NE1236C50* |

12 x 36 |

4.5†‡ |

Standard |

2.02 |

36.3 (922) |

13 (5.9) |

9 |

| NE1242C20* |

12 x 42 |

2.5 |

Standard |

2.41 |

42.4 (1077) |

15 (6.8) |

9 |

| NE1242C40* |

12 x 42 |

4.0† |

Standard |

2.41 |

42.4 (1077) |

15 (6.8) |

9 |

| NE1242C50* |

12 x 42 |

4.5†‡ |

Standard |

2.41 |

42.4 (1077) |

15 (6.8) |

9 |

| NE1244C20* |

12 x 44 |

2.5 |

Standard |

2.53 |

44.5 (1130) |

15 (6.8) |

9 |

| NE1244C40* |

12 x 44 |

4.0† |

Standard |

2.53 |

44.5 (1130) |

15 (6.8) |

9 |

| NE1248C20* |

12 x 48 |

2.5 |

Standard |

2.78 |

48.5 (1232) |

16 (7.3) |

9 |

| NE1248C40* |

12 x 48 |

4.0† |

Standard |

2.78 |

48.5 (1232) |

16 (7.3) |

9 |

| NE1252C20* |

12 x 52 |

2.5 |

Standard |

3.06 |

52.8 (1341) |

17 (7.7) |

9** |

| NE1252C40* |

12 x 52 |

4.0† |

Standard |

3.06 |

52.8 (1341) |

17 (7.7) |

9** |

| NE1252C50* |

12 x 52 |

4.5†‡ |

Standard |

3.06 |

52.8 (1341) |

17 (7.7) |

9** |

|

| |

| 13 INCH DIAMETER TANKS |

For Bottom Plate substitute "U" for "C" in Part Number;

For Mid Plates substitute "V" for "C" in Part Number;

For Bottom and Mid Plates substitute "X" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE1330C20* |

13 x 30 |

2.5 |

Standard |

1.95 |

30.0 (762) |

12 (5.4) |

12 |

| NE1335C20* |

13 x 35 |

2.5 |

Standard |

2.34 |

35.1 (892) |

14 (6.4) |

12 |

| NE1344C20* |

13 x 44 |

2.5 |

Standard |

3.03 |

44.4 (1128) |

18 (8.2) |

9 |

| NE1348C20* |

13 x 48 |

2.5 |

Standard |

3.33 |

48.3 (1227) |

20 (9.1) |

9 |

| NE1354C20* |

13 x 54 |

2.5 |

Standard |

3.74 |

54.3 (1379) |

22 (10.0) |

9** |

| NE1360C20* |

13 x 60 |

2.5 |

Standard |

4.24 |

60.6 (1539) |

25 (11.4) |

1 |

| NE1365C20* |

13 x 65 |

2.5 |

Standard |

4.59 |

65.1 (1654) |

26 (11.8) |

1 |

|

| |

| 14 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE1430C20* |

14 x 30 |

2.5 |

Standard |

2.15 |

30.1 (765) |

15 (6.8) |

10 |

| NE1430C40* |

14 x 30 |

4.0† |

Standard |

2.15 |

30.1 (765) |

15 (6.8) |

10 |

| NE1447C50* |

14 x 47 |

4.5†‡ |

Standard |

3.65 |

47.9 (1216) |

23 (10.5) |

8 |

| NE1454C20* |

14 x 54 |

2.5 |

Standard |

4.17 |

54.1 (1375) |

25 (11.4) |

8** |

| NE1454C40* |

14 x 54 |

4.0† |

Standard |

4.17 |

54.1 (1375) |

25 (11.4) |

8** |

| NE1465C20* |

14 x 65 |

2.5 |

Standard |

5.10 |

65.1 (1654) |

29 (13.2) |

1 |

| NE1465C40* |

14 x 65 |

4.0† |

Standard |

5.10 |

65.1 (1654) |

29 (13.2) |

1 |

| NE1465C50* |

14 x 65 |

4.5†‡ |

Standard |

5.10 |

65.1 (1654) |

29 (13.2) |

1 |

| NE1472C20* |

14 x 72 |

2.5 |

Standard |

5.69 |

72.1 (1832) |

32 (14.5) |

1 |

| NE1472C40* |

14 x 72 |

4.0† |

Standard |

5.69 |

72.1 (1832) |

32 (14.5) |

1 |

|

| |

| 16 INCH DIAMETER TANKS |

| For Bottom Plate substitute "U" for "C" in Part Number |

Part

Number |

Tank Size

Inches |

Top

Opening

Inches |

Base

Style |

Capacity

Cu. Ft. |

Height

with Base

inch (mm) |

Tank

Net Wt.

Lbs. (kg) |

Carton

Quantity |

| NE1623C20* |

16 x 23 |

2.5 |

Standard |

2.06 |

23.1 (587) |

17 (7.7) |

1 |

| NE1623C40* |

16 x 23 |

4.0† |

Standard |

2.06 |

23.1 (587) |

17 (7.7) |

1 |

| NE1628C20* |

16 x 28 |

2.5 |

Standard |

2.61 |

28.0 (711) |

19 (8.6) |

1 |

| NE1628C40* |

16 x 28 |

4.0† |

Standard |

2.61 |

28.0 (711) |

19 (8.6) |

1 |

| NE1636C20* |

16 x 36 |

2.5 |

Standard |

3.62 |

36.5 (927) |

21 (9.5) |

1 |

| NE1636C40* |

16 x 36 |

4.0† |

Standard |

3.62 |

36.5 (927) |

21 (9.5) |

1 |

| NE1644C20* |

16 x 44 |

2.5 |

Standard |

4.53 |

44.2 (1124) |

25 (11.4) |

1 |

| NE1644C40* |

16 x 44 |

4.0† |

Standard |

4.53 |

44.2 (1124) |

25 (11.4) |

1 |

| NE1653C20* |

16 x 53 |

2.5 |

Standard |

5.57 |

53.3 (1353) |

30 (13.6) |

1 |

| NE1653C40* |

16 x 53 |

4.0† |

Standard |

5.57 |

53.3 (1353) |

30 (13.6) |

1 |

| NE1665C20* |

16 x 65 |

2.5 |

Standard |

6.91 |

64.7 (1643) |

33 (15.0) |

1 |

| NE1665C40* |

16 x 65 |

4.0† |

Standard |

6.91 |

64.7 (1643) |

33 (15.0) |

1 |

|

| |

* Specify color: 'A'=Almond; 'B'=Blue; 'G'=Gray; 'K'=Black; 'N'=Natural. If not specified, SWT will supply Black.

** Tanks 50 inch or taller with extended base require single carton for shipment.

† Top opening with machined threads.

‡ Buttress with rubber bumper. |

| |

Extended Base Option: Available for 7 to 16 inch diameter tanks.

Super-Extended Base Option: Available for 14 and 16 inch diameter tanks.

Rubber-Like Base for DI Exchange Tanks Option: Available for 12 and 14 inch diameter tanks.

Bottom Opening Option: 2.5 inch NPSM for 7 to 16 inch diameter tanks; 4 inch UN for 12, 14, and 16 inch diameter tanks.

Dome Hole Option: 1.25 inch with closure for 10, 12, and 13 inch diameter tanks.

Side Openings Not Available.

Bumper Band Option: Available for 7 to 14 inch diameter tanks. |

| |

TANK WARRANTY:

Residential polypropylene-lined pressure vessels (up to 13 inch diameter) are warranted to be free of manufacturing and material defects for a period of 10 years if operated within specifications in residential water treatment applications. Commercial and industrial sizes (greater than 13 inch diameter) are warranted for a period of 5 years. Warranty coverage excludes freezing, vacuum, corrosive materials exposure.

These vessels are only approved for H2O pressure use. All other uses or solutions to be used must be approved by manufacturer.

These vessels are not to be used for pneumatic or hydro-pneumatic applications. |

| |

| |

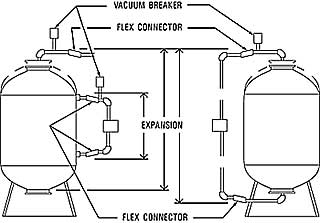

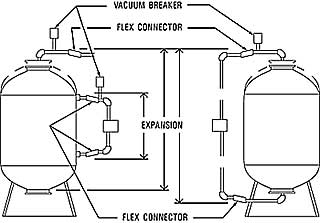

| VACUUM PROTECTION & FLEX CONNECTORS |

Fiberglass/composite pressure vessels are rated for an internal negative pressure of 5-inches Hg (17 Pa) vacuum below atmospheric. If negative pressure could ever exceed 5-inches Hg (17 Pa), an adequate vacuum breaker must be installed between the pressure vessel inlet and any valves (see illustration right). For enclosed tank applications, the vacuum breaker should be installed at the highest location in the system plumbing.

System connections to the pressure vessel must accomodate vertical expansion between side, top, and bottom openings. Either flexibility in piping or flex connectors, as shown here, are recommended. |

|

See SWT Vacuum Protection

and Flex Connector Products |

|

| |