| Softening Resin |

|

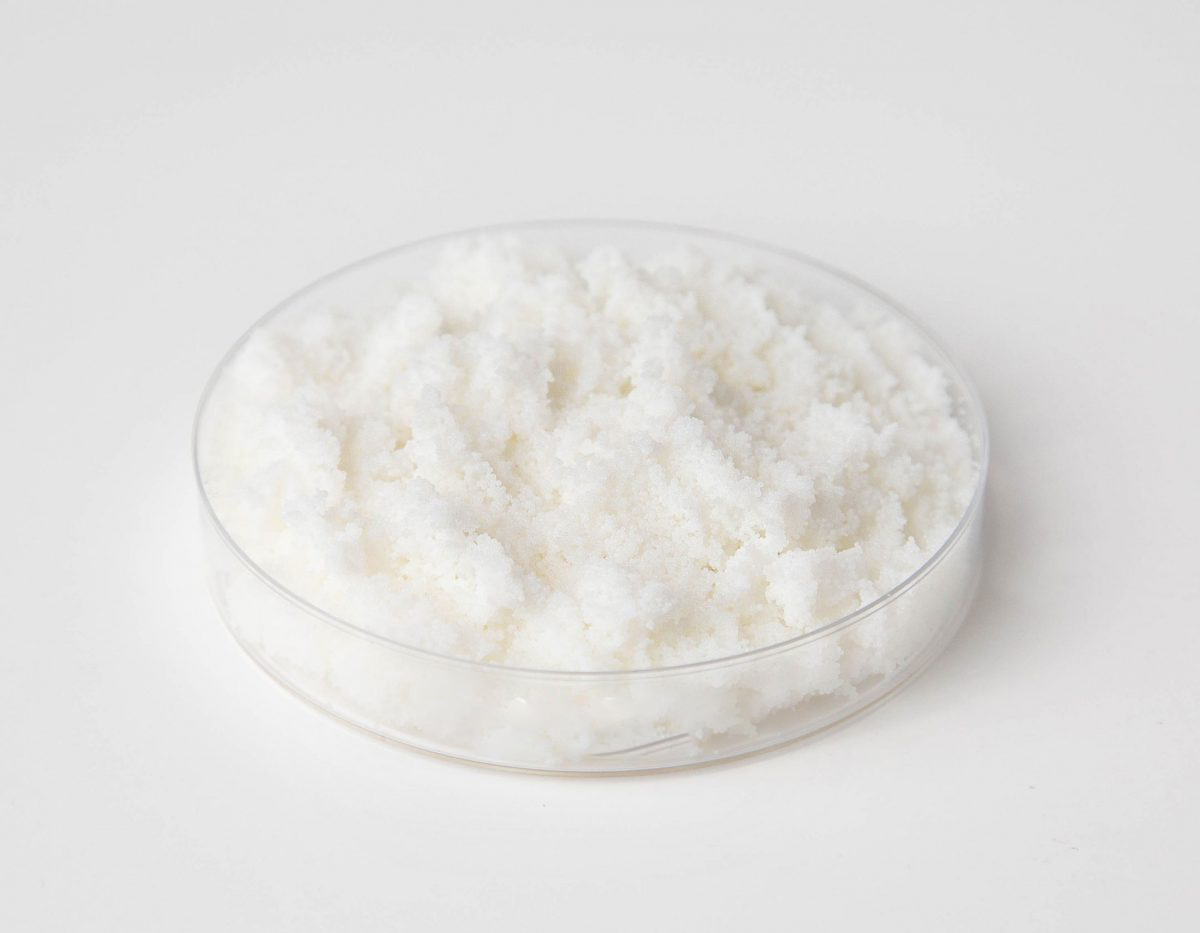

ProSoft™ ER10011-MP |

| Request For Quote | |

| ProSoft™ ER10011-MP (P/N ER10011-MP) is a premium grade, weak acid, macro-porous, cation resin supplied in the hydrogen form (also available in the sodium form) as moist, tough, uniform, spherical beads. Its ion exchange functionality is derived from the carboxylic group, which is easily converted to the hydrogen form and has a high affinity for divalent ions. It is intended for use in hydrogen cycle dealkalization, deionization, and chemical processing applications. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||