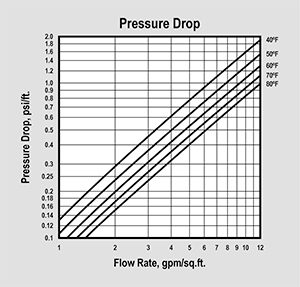

GreensandPlus is effective at higher operating temperatures and higher differential pressures than ordinary manganese greensand. Tolerance to higher differential pressure can provide for longer run times between backwashes and a greater margin of safety.

Systems may be designed using either vertical or horizontal pressure filters, as well as open gravity filters.

GreensandPlus is a proven technology for iron, manganese, arsenic, radium, and hydrogen sulfide removal. Unlike in-situ treated media, there is no need for extensive preconditioning of filter media or lengthy startup periods, during which required water quality may not be met.

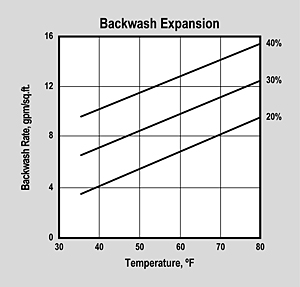

GreensandPlus is an exact replacement for manganese greensand. It can be used in CR or IR applications and requires no changes in backwash rate or times or chemical feeds.

|

pH

Raw waters having natural pH of 6.2 or above can be filtered through GreensandPlus without pH correction. Raw waters with a pH lower than 6.2 should be pH-corrected to 6.5 to 6.8 before filtration. Additional alkali should be added following the filters if a pH higher than 6.5 to 6.8 is desired in the treated water. This prevents the possible adverse reaction and formation of a colloidal precipitate that sometimes occurs with iron and alkali at a pH above 6.8.

RADIUM AND ARSENIC REMOVAL USING GREENSANDPLUS

The GreensandPlus CR process has been found to be successful in removing radium and arsenic from well water. This occurs via adsorption onto the manganese and/or iron precipitates that are formed. For radium removal, soluble manganese must be present in or added to the raw water for removal to occur. Arsenic removal requires iron to be present in or added to the raw water to accomplish removal. Pilot plant testing is recommended in either case. |