| MTM consists of a light weight granular core with a coating of manganese dioxide. The coating provides an example of contact filtration where the media itself provides the oxidizing potential. This allows for a much broader range of operation than many other iron removal medias. A pH level as low as 6.2 can be treated. Dissolved oxygen is not essential. The media’s light weight reduces backwash water requirements. |

| |

| |

|

| |

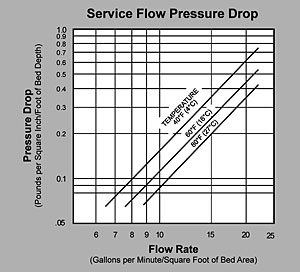

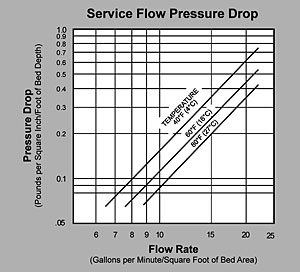

| PRESSURE DROP — The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures. |

| |

| |

|

| |

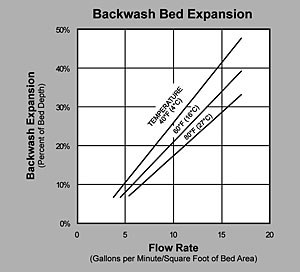

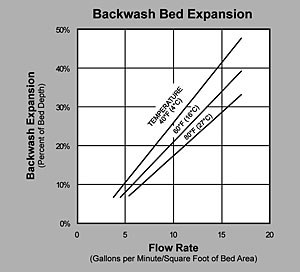

| BACKWASH — After each cycle the media bed should be backwashed at a rate that expands the bed 20 to 40 percent. |

| |

| |

When the oxidizing power of MTM is reduced, the bed has to be regenerated with a weak solution of potassium permanganate (KMnO4), thus restoring its oxidizing capacity. A regenerating solution of 1½ to 2 ounces (dry weight) of potassium permanganate per cubic foot is sufficient for normal regeneration. Upon startup a new bed should be backwashed and caution taken to insure that the lightweight media is not backwashed to drain. A new bed should be regenerated the evening of installation. Operating the filter after its oxidizing capacity is exhausted will reduce its service life and may cause staining.

MTM requires either intermittent or continuous regeneration to maintain its oxidizing capacity. A solution of potassium permanganate (or chlorine then potassium permanganate) can be pre-fed to maintain capacity. In the latter case, the manganese dioxide coating acts as a catalyst to enhance the oxidation reaction and as a buffer to reduce any excess potassium permanganate concentration and prevent it from entering the service lines.

The addition of other chemicals to influent or backwash water which contacts MTM media may inhibit iron, manganese, or hydrogen sulfide removal, or may break down or coat MTM media. Before adding any chemical to the influent or backwash water, other than chlorine or potassium permanganate, the chemical’s compatibility with MTM should be thoroughly tested. |

| |

|

|

Certified to NSF/ANSI Standard 61

|

|

|

|

| |

Features: |

|

| |

• |

Broad operating range for iron reduction |

|

| |

• |

Lower pressure loss through the bed with high flock holding capacity |

|

| |

• |

Effective hydrogen sulfide, iron, and manganese reduction |

|

| |

• |

Light weight requires lower backwash rates and reduces pumping requirements |

|

| |

• |

Chlorine can be beneficial in extending filter run times |

|

| |

• |

Low attrition loss for long bed life |

|

| |

• |

Lower shipping cost |

|

| |

• |

Certified to NSF/ANSI Standard 61 |

|

|

| |

| |

| TYPICAL PROPERTIES |

| Part Number |

MTM |

| Color |

Dark brown |

| Specific Gravity |

2.0 gm/cc |

| Effective Size |

0.43 mm |

| Uniformity Coefficient |

2.0 |

| Mesh Size |

12 x 50 |

| Net Weight |

45 to 50 lb / cu.ft. |

| Packaging |

1 cu.ft. bag |

|

| |

| SUGGESTED OPERATING CONDITIONS |

| Water pH Range |

6.2 to 8.5 |

| Water Temperature |

100°F (38°C) maximum |

| Bed Depth |

24 to 36 inches |

| Freeboard |

50% minimum |

| Service Flow Rate |

2 to 5 gpm/sq.ft. continuous

(Intermittent flows up to

10 gpm/sq.ft.) |

Backwash Flow Rate

12 inch tanks and smaller

13 inch tanks and larger |

8 to 10 gpm/sq.ft. @ 60ºF

10 to 12 gpm/sq.ft. @ 60ºF |

| Backwash Bed Expansion |

20 to 40% of bed depth min. |

|

| |

| MAXIMUM PRACTICAL LIMIT |

| Iron |

15 ppm |

| Manganese |

5 ppm |

| Hydrogen Sulfide |

2 ppm |

|

| |

| INFLUENT AND BACKWASH LIMITATIONS |

| Oil |

None present |

| Polyphosphates |

None present |

| Air Scour |

Not allowed |

|

| |

| CONTINUOUS REGENERATION |

| Use Cl2, KmnO4, or both |

|

| |

| INTERMITTENT REGENERATIONS |

| KMnO4 Dosage |

1.5 to 2.0 oz (dry wt.)/cu.ft. |

| Regeneration Time |

30 minutes minimum |

| Rinse |

Until all traces of KMnO4 are gone |

| 10,000 gallons water containing 1 mg/L iron per cu.ft. regeneration |

| 5,000 gallons water containing 1 mg/L manganese per cu.ft. regeneration |

| 2,000 gallons water containing 1 mg/L hydrogen sulfide per cu.ft. regeneration |

| For dilute solutions mg/L = ppm |

| 37,850 mg KmNO4 demand |

| KMnO4 demand = [1 x mg/L Fe] + [2 x mg/L Mn] + [5 x mg/L H2S] |

|

ADDITIONAL INFORMATION:

View SWT Filtration Media Guide

Iron Removal Comparison Chart |

| |

| |

|

California Proposition 65 Warning

This product contains crystalline silica which is known to the State of California to cause cancer and other substances which are known to the State of California to cause cancer, birth defects, and reproductive harm.

|

| |

| |

|

This filter media does not remove or kill bacteria. Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

|

| |

| |

|

This information has been gathered from standard materials and or test data that is believed to be accurate and reliable. Nothing herein shall be determined to be a warranty or representation expressed or implied with respect to the use of such information or the use of the goods described for any particular purpose alone or in combination with other goods or processes, or that their use does not conflict with existing patent rights. No license is granted to practice any patented invention. It is solely for your consideration, investigation and verification.

|

| |

| |

| MTM® is a registered trademark of Clack Corporation. |

|